Your advantages as a JUD customer

- More than 130 years of tradition & experience as a family business!

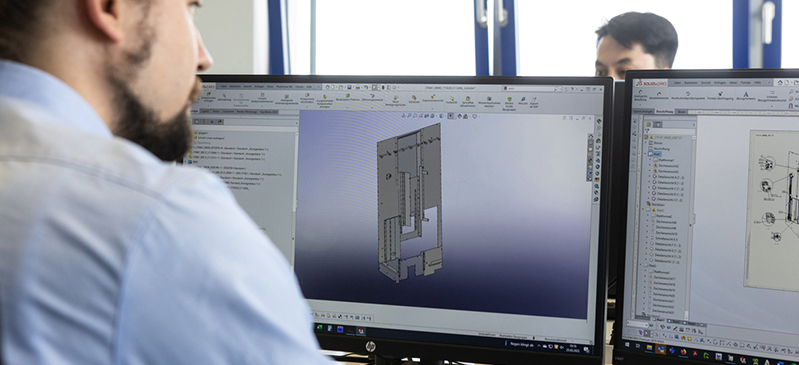

- Modern and extensive machinery!

- Variety of mastered production processes! Everything from one source!

- Possibility to offer complete solutions to our customers!

- Experienced design engineers and experienced staff team!

- Environmentally conscious production! Photovoltaic system - E-vehicles - Recycling - Sustainability!

- Holistic corporate management via the ERP system SAP!

- Own transport fleet for smooth deliveries!

- High adherence to delivery dates and quality, as well as fair and market-driven prices!

Experts in metalworking – active in environmental protection

Five generations develop and shape a company: the family business, JUD GmbH & Co. KG.

Founded in 1889 by Wilhelm Karl JUD in Stuttgart, the company is one of the pioneers of metalworking in Baden-Wuerttemberg. Today, the innovative company employs over 100 people in Waiblingen, conveniently located in the industrial region of Stuttgart.

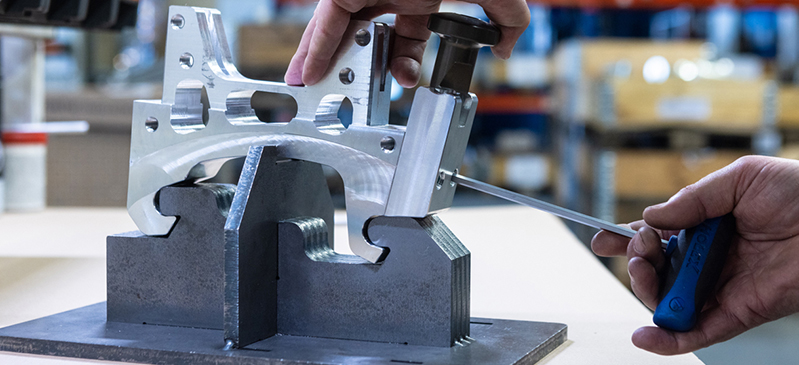

In modern halls, with a total production area of over 10,000 square meters, the JUD company produces versatile and modern machinery. The machines and production facilities come from renowned manufacturers and have been optimised through many years of experience and with an inventive spirit for the respective tasks. Materials such as steel, stainless steel, aluminium and various non-ferrous metals are used – from individual parts to complete solutions.

We provide the following services:

Metalworking according to customer requirements

We produce either directly according to the specifications of our industrial customers or in the form of a complete solution that includes conception and development, modelling, testing and prototyping.

The service portfolio includes individual and unique parts, multi-stage assembly and welded assemblies of complex plant components that are used in the construction and agricultural machinery industry, special vehicle construction, air-conditioning and clean room technology, the furniture industry, and mechanical and plant engineering.

As a partner, we actively support you in reducing the vertical range of manufacture and the number of suppliers. We join components with different processes such as welding, soldering, riveting, glueing and clinching and assemble them into complete assemblies for you.

Innovation, knowledge and experience in all aspects of metalworking: laser cutting and forming of sheet metal and tubes, machining, welding, assembling and powder coating – as a certified company according to DIN ISO 9001:2015 and for welding work according to DIN EN ISO 3834-2:2006, we are the ideal cooperation partner in the field of small and medium series up to quantities of several thousand per year.

We focus on sustainability!

We produce significant parts of our consumed electricity in an environmentally friendly way with our large-scale, in-house photovoltaic system. We also use this sustainably produced electricity to operate our company-owned electric and hybrid vehicles.

In addition, we minimise our material consumption through optimal material use on all machines and consistent recycling of residual materials.

Through this holistic approach, we make a valuable contribution to reducing CO₂ emissions and thus protecting our environment!